In such economic hardships, cuts and better strategies need to be put in situ so as for your business to survive. So here are ten top tips which can enable you to enhance what proportion you spend without affecting the standard or efficiency:

Number One: you’ll cut out the wholesaler (otherwise know because the middle man!).

This will:

- Make the distribution process more speedy as you’ll be delivering on to the customer

- You will cut costs

- Are ready to sell more products because you’ll be ready to offer better prices

Number Two: Improve the tracking in your product, which will:

- cut down competitors copying your product

- enable you to remain before your competition by being more efficient

Number Three: Improve your technologies within the manufacturing process.

- Therefore the products are going to be created quickly and efficiently.

- Enhancing your technology within the process will hopefully help to chop the value of creating the merchandise in order that you’ll sell it at a more competitive price.

- It will also make the manufacturing process more efficient if you update the equipment.

Number Four: you’ll outsource the manufacturing to new markets like India or China, which will:

- Cut labour costs because it’ll be cheaper there

- You will be ready to make your products cheaper

Number Five: make sure that internal control is kept as best because it are often .

- If you’ve got good quality products this may increase sales.

- When you properly analyse the standard of your products then it could stop disastrous results which will hurt the corporate which successively will cost tons of cash

- As you’ll remember , within the pharmaceutical industry there’s little room for mistakes

- Additionally, this industry is extremely competitive and thus if you produce anything that’s under the expected quality it could mean that your contracts may move to competitors.

Number Six: Have a correct analysis of where you’re spending your money is going:

- If you perform this analysis then you’ll determine where you’ll cut costs and make budgeting better

Number Seven: you ought to cut costs in areas where there’s tons of wastage or money isn’t getting used efficiently.

In every industry there’ll always be areas where money isn’t getting used as effectively because it might be used. Your thorough analysis will show up any wastage in your company.

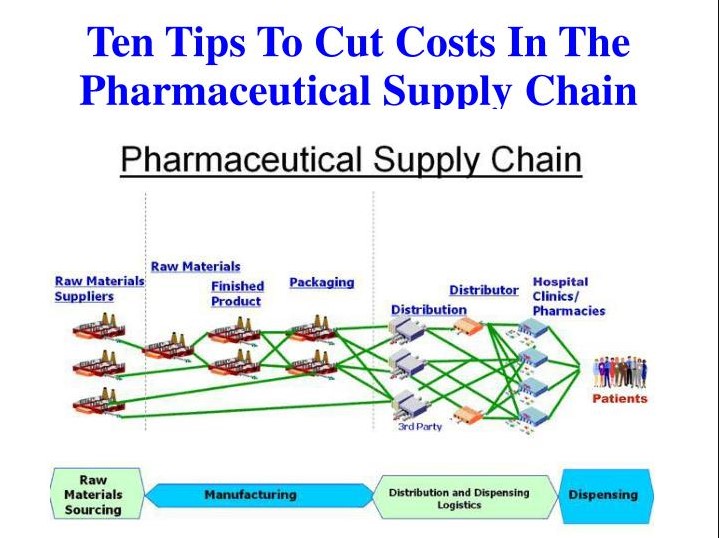

Number Eight: you’ll conduct as supply chain analytics.

This when a business scrutinises the entire supply chain process. it’ll allow you to assess the areas that require to be improved. the availability chain is extremely complex because you’ll affect several suppliers on a worldwide scale. Certain questions got to be asked such as; which suppliers are the foremost efficient, what factors effect the availability chain, are you overstocking or understocking?

Number Nine:

once you have conducted a supply chain analysis then you ought to quickly implement the required changes to the availability chain so as to extend efficiency and cut costs to the availability chain.

Number Ten: Examine your purchasing team

this will:

- Ensure that you’re getting top quality products without spending an excessive amount of money

- You may got to change suppliers to decrease the prices but confirm that you simply keep the standard to a maximum effect.

- Make sure that you simply get detailed data from the purchasers in order that you’ll analyse how efficient and cost- effective you’re being.